GENERAL INFORMATIONS

GENERAL INFORMATIONS

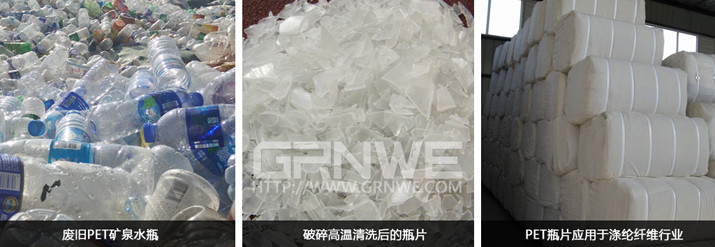

The plant is mainly used for crushing and washing waste pet bottles and plastic into cleanly flakes, it plays an important role in the pet plastic recycling.

Technological process:

Label removing

→ Crushing the material into fakes (dry or wet)

→ Separating cap and rings→ Cold washing

→ hot washing

→ floating washing

→ drying

→ Second crushing

→ Separating the impurity

→ compress baling.

According to the bottle situation (the bottle size, label design, etc), GRNWE provides different proposals for customers’ choice in label removing process, and GRNWE could meet different requests of customers

by years’ plastic recycling experience, customize the best proposal(including technical process, factory requirement plan, water recycling system) for you !

FEATURES

FEATURES

GRNWE insists the idea of “Always seeing things through customers ‘ eyes”, absorbing and combining the foreign plastic recycling technology with our years’ experience, GRNWE maintains the competitiveness and advantage in the plastic recycling market by improving the technology, keeping expend the PET recycling area according to the trend of the plastic recycling market.

● In the filament yarn level PET recycling area, GRNWE has the progressive waste water recycling system, the maximum capacity could reach 5600kg/hour.

● In plastic impregnated level PET recycling area, GRNWE was one of the domestic manufactures that bring PET recycling material into synthetic resin industry, replacing the petrochemical material in original formulation, reducing the cost of synthetic resin manufacture, GRNWE had the successes case for 2000 tons per month in synthetic resin level pet recycling.

● No matter the purity level or the plant capacity, GRNWE has large market share in the plastic recycling industry, GRNWE is improving in “bottle to bottle” high-end technical area and had breakthroughs in ultrasonic washing process. GRNWE’s target is being the first manufacture of “bottle to bottle” recycling equipment.

● The pet recycling plant uses “second crushing” after the drying process and double screw blade design, making sure the low consumption of flake powder and high output capacity.

● Maintaining the high quality and low power/water consumption, GRNWE uses the high energy efficiency power source and high efficiency water recycling system according to different function of water using in different process.

MODELS

MODELS

|

MODEL |

CAPACITY (Kg/h) |

POWER (Kw) |

WATER CONSUMPTION (m³/h) |

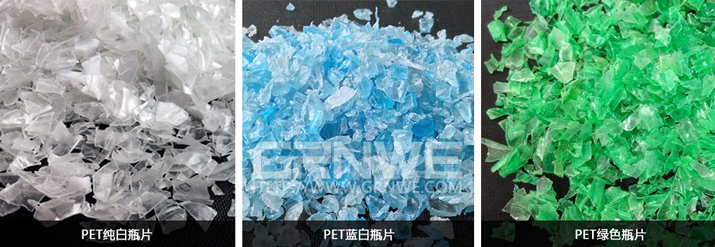

BOTTLE FLAKES LEVELS |

AREA COVER(m) |

MAN POWER |

LEAD TIME(DAYS) |

|

GWETC-1000 |

500-800 |

70 |

3 |

Cold washing bottle flakes |

L42*W2.0*H3.5 |

5 |

20 |

|

GWETH-1000 |

120 |

5 |

Hot washing 3D short fiber level pet flakes |

L62*W2.2*H3.5 |

5 |

25 |

|

|

GWETS-1000 |

130 |

6 |

Hot washing filament yarn level pet fakes |

L65*W2.2*H4.5 |

5 |

30 |

|

|

GWETC-1500 |

1300-1500 |

85 |

4 |

Cold washing bottle flakes |

L42*W2.5*H3.5 |

5 |

20 |

|

GWETH-1500 |

140 |

7 |

Hot washing 3D short fiber level pet flakes |

L62*W2.5*H3.5 |

5 |

25 |

|

|

GWETS-1500 |

150 |

8 |

Hot washing filament yarn level pet fakes |

L65*W2.5*H4.5 |

5 |

30 |

|

|

GWETC-2000 |

1800-2000 |

100 |

5 |

Cold washing bottle flakes |

L42*W2.0*H3.5 |

5 |

25 |

|

GWETH-2000 |

160 |

8 |

Hot washing 3D short fiber level pet flakes |

L82*W4.2*H3.5 |

5 |

30 |

|

|

GWETS-2000 |

180 |

10 |

Hot washing filament yarn level pet fakes |

L85*W4.2*H4.5 |

5 |

30 |

Remark: Above models are general models of GRNWE, please contact us if you needed plastic impregnated level/ synthetic resin level or other models.